The propeller installation has been installed traditionally on a tapered shaft with a nut and using a key as locking device. This operation method is not only difficult due to high forces involved, it also very time consuming. Also when uninstalling propellers traditionally fitted with this method, it becomes a harder task as required forces are even higher due to possible fretting that can occur.

In order to minimize the installation/un-installation risks and time, the use of hydraulically fitted propellers can be used. Wärtsilä can offer the solution to simplify the process and reduce the amount of force required.

The hydraulic nuts are available in a wide range of sizes.

FEATURES & BENEFITS

- Simplify the operation process and maintenance.

- Reduces the shaft finish requirements as no keyways need to be machined.

- Designed to ensure the shortest installation/un-installation time with the minimum staff.

- Avoid leakages during installation/uninstallation.

- More controllable installation/ uninstallation process.

- Eliminates the risks of fretting and stress raisers produced by keyway machining.

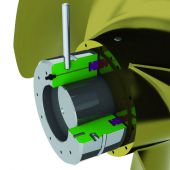

Hydraulic nut assembly consists of two elements:

- Nut body: This is an alloy steel ring internally threaded with a groove in one of its faces.

- Piston nut: It is the mobile part of the nut and is located in the nut body groove. This element is pushed by the hydraulic pressure and exerts the axial force.

Hydraulic nuts are made with high quality standard materials and complies with all requirements of the most exigent international societies standards. Also detailed manufacture and control procedures gives a perfect-ready to install product.

Special designs and modifications made over our standard design are possible under customer request.