The traditional, rigid engine installation...

In traditional installations, the engine must be very precisely aligned to the propeller shaft. The thrust of the propeller has to be absorbed by the engine and its mounts. These restrictions demand very stiff mounts which transmit high levels of vibration to the hull.

...or superior engineering through Aquadrive®

The Aquadrive® anti-vibration system eliminates the need for stiff, hard mounts and for careful engine alignment to the propeller shaft. Instead, the propeller shaft is aligned to an Aquadrive® thrust bearing which absorbs all the propeller thrust and stabilizes the alignment. CV-joint shafts transmit engine power to the thrust-bearing and propeller shaft while allowing engine movements in every direction. Super-soft Aquadrive® engine-mounts isolate nearly all vibration from the hull and create the necessary conditions for a smooth and quiet boat.

Easier engine installations and permanent alignment

Aquadrive® systems utilize CV-shafts to allow extreme misalignment and engine movement. The system automatically adjusts to any changes in alignment between the engine and thrust bearing. Unlike standard marine engine installations, alignment is more easily accomplished and should not require periodic adjustments.

Torsional damping and Aquadrive® systems

Soft, flexible rubber elements are normally installed between the engine flywheel and gearbox to avoid torsional vibration. Aquadrive® CV-shafts can be directly coupled to those gearboxes without additional rubber or flexible elements. For flywheel-mounted installations, Aquadrive® torsional rubber dampers combined with CV-shafts (CVT-units) are available in a full range of power applications involving remote-mounted propulsion equipment, such as water-jets, stern drives and remote v-drives.

AQUADRICE SYSTEM

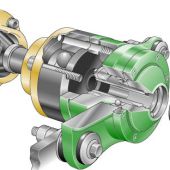

CV Shaft

The drive shaft of variable length includes two true plunging Constant Velocity joints that work independently at any angle. This eliminates the need for accurate engine alignment, either during initial installation or subsequent use. The rolling action of the balls within the CV joints absorb all axial and radial loads, permitting the use of very soft engine mounts as well as reducing wear in connected bearings. A range of pre-machined adapter kits allows coupling to almost any marine gearbox.

Thrust Bearing

Aquadrive thrust bearing with rubber mounts attach to a cross brace in the hull. Massive bearings transfer the thrust directly to the hull and not the engine. In addition, the propeller shaft is much better supported, leading to smoother running and less wear on the stern seal.

Engine Mounts

Aquadrive’s proven engine mounts are softer than almost any other and should be used to take full advantage of the system. These mounts are steel hooded to prevent diesel damage and fully captive so that the engine cannot leave its frame even if the vessel is turned over.